Full Project Scope

From inquiry until commissioning.

Preliminary studies

Evaluating the performance of an already existing heat exchanger creates a foundation to understand the maximum heat recovery potential of any plant.

For this purpose, we create a thermodynamical model of the plant and consider all relevant process parameters, as well as the configuration of the currently installed equipment.

As a result, our customers become empowered to make the most viable investment choice for their specific project.

Acid condensation estimates

Tramp air assessment

Performance optimization

Cold end protection evaluation

Integrative engineering

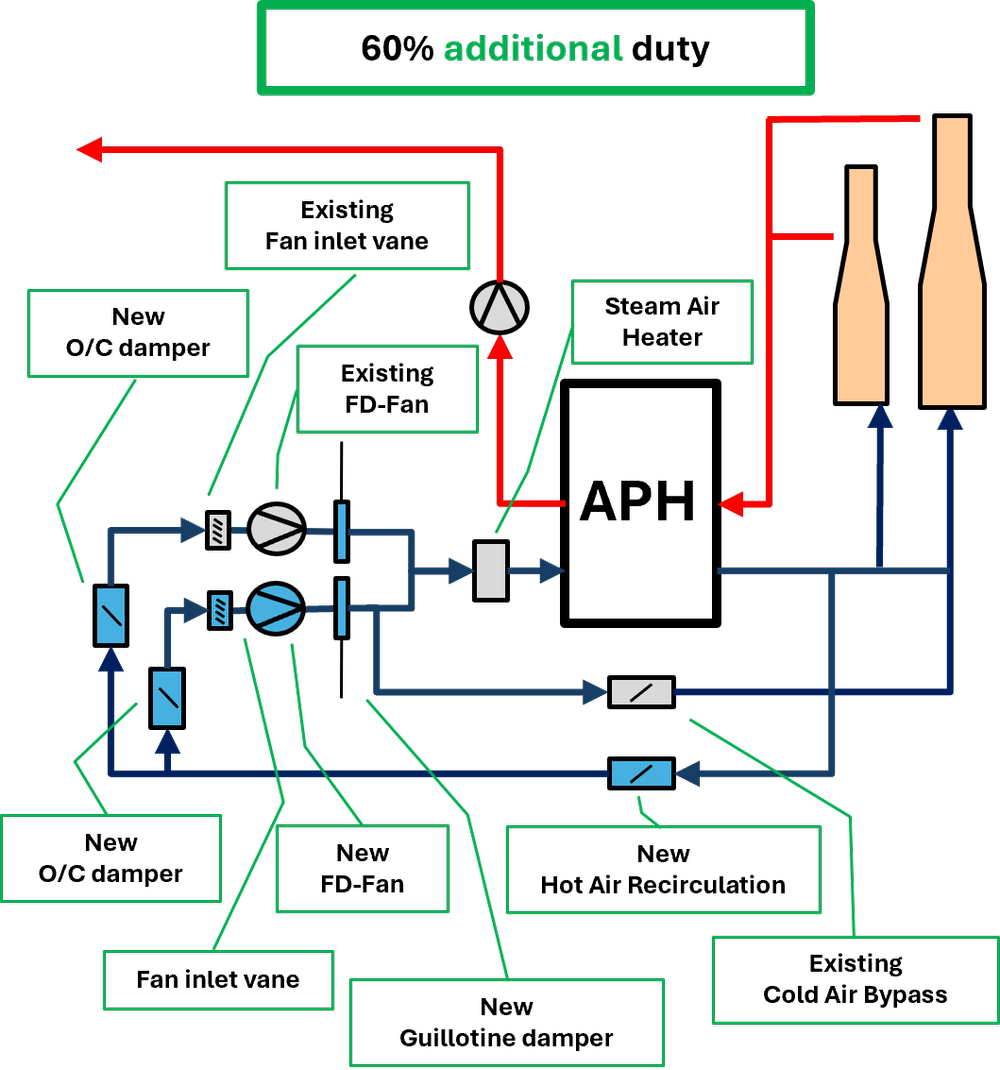

We adapt our mechanical design to the specified weight and space restrictions on site. By integrating auxiliary structural elements, we can deliver flexible turn-key solutions that facilitate project execution.

Our engineering services regarding mechanical design include heat exchanger modules, inlet and outlet distribution hoods, stress calculations and auxiliary structural elements.

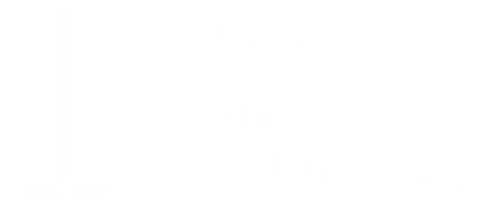

The latter may include cold and hot gas bypasses, dampers, connecting ducts, steel support structure, expansion joints and more.

Stress reports

Connecting ducts

Cold air bypass

Auxiliary steel structures

Hot air recirculation

Adaptive manufacturing

In our workshop, we focus on producing heat exchanger plate packs. A network of partners and suppliers extends our scope to complex external steel structures, depending on the challenges of each project.

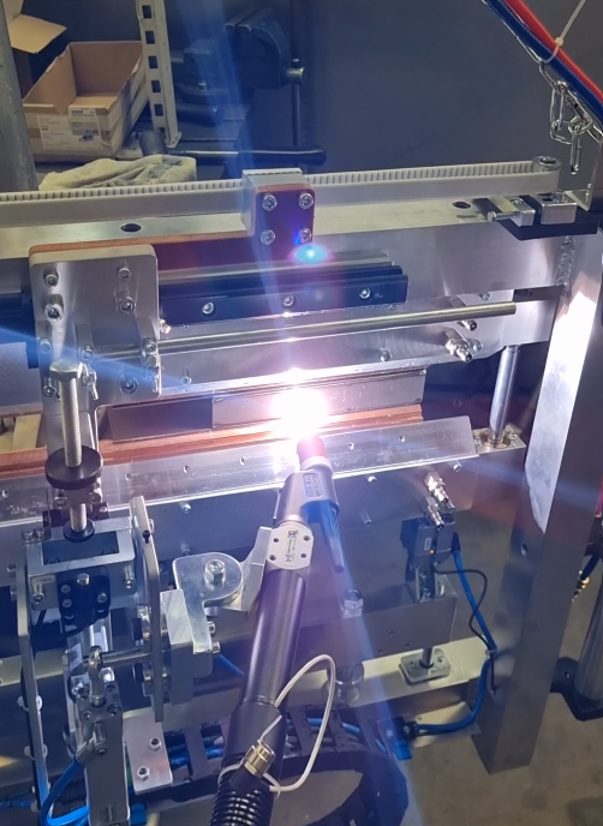

We use state of the art manual, semi-mechanical and fully-mechanical welding technologies to guarantee tight seal welds for zero leakage.

Our trained personnel and experienced partners conduct inspections at various stages of the production process to ensure the quality of the equipment.

Flexible fabrication and deep understanding help us choose, mix and evolve the optimal flow pattern for plants and applications: counter-flow, cross-flow or counter-cross combinations.

Heat exchanger modules are typically arranged in either one single pass or in multi passes, depending on the heat recuperation targets.

Single stage and multi-stage towers

Counter- & cross- flow

Carbon steel &

austenitic steel

Installation & supervision

Experienced partner companies perform the necessary works once the heat exchanger modules has arrived on site. Our supervisors ensure the correct delivery, installation and start-up of the equipment.

During the installation phase, we manage sub-contractor tasks and ensure the timely execution of the project schedule.

Supervision

Commissioning

A team at your service

We will be happy to offer the best solution that suits your business.

Save money with our solutions

Reduce your fuel consumption and CO2 emissions