Seal-welded, plate-type heat exchangers.

Compact. Efficient. Innovative.

Combustion air preheaters

Counter-flow

configuration

Cross-flow

configuration

Counter-cross

combinations

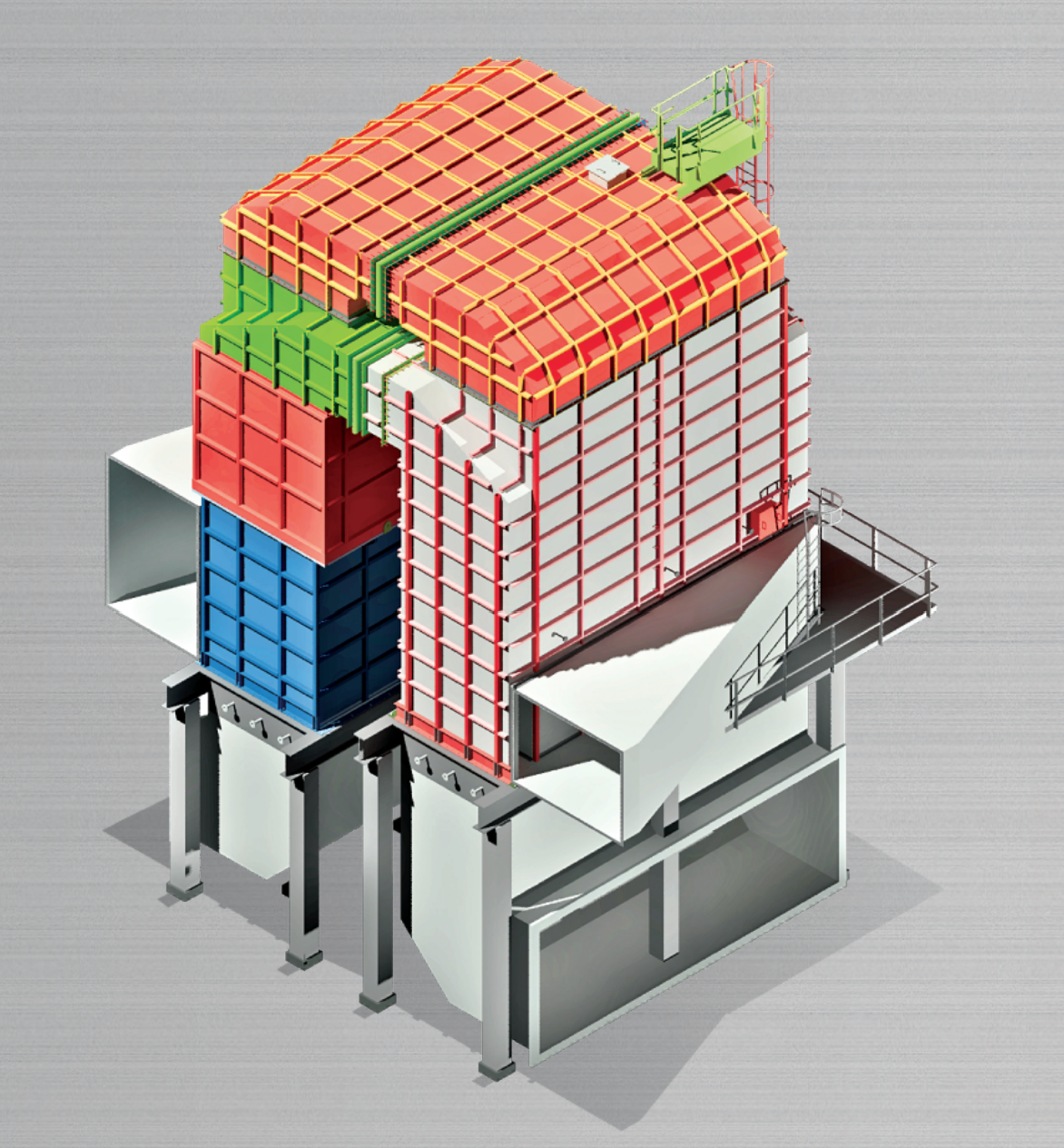

Flue gas reheaters

For flue gas reheater projects, we bring the same versatiliy and experience to the table as with our combustion air pre-heaters. An additional advantage of our design lies in the compatibility with already installed counter flow plate-type heat exchangers, making module replacement an economically highly viable option.

Ultra compact design

Optimized corrosion resistance

Highest thermal efficiency

Zero leakage

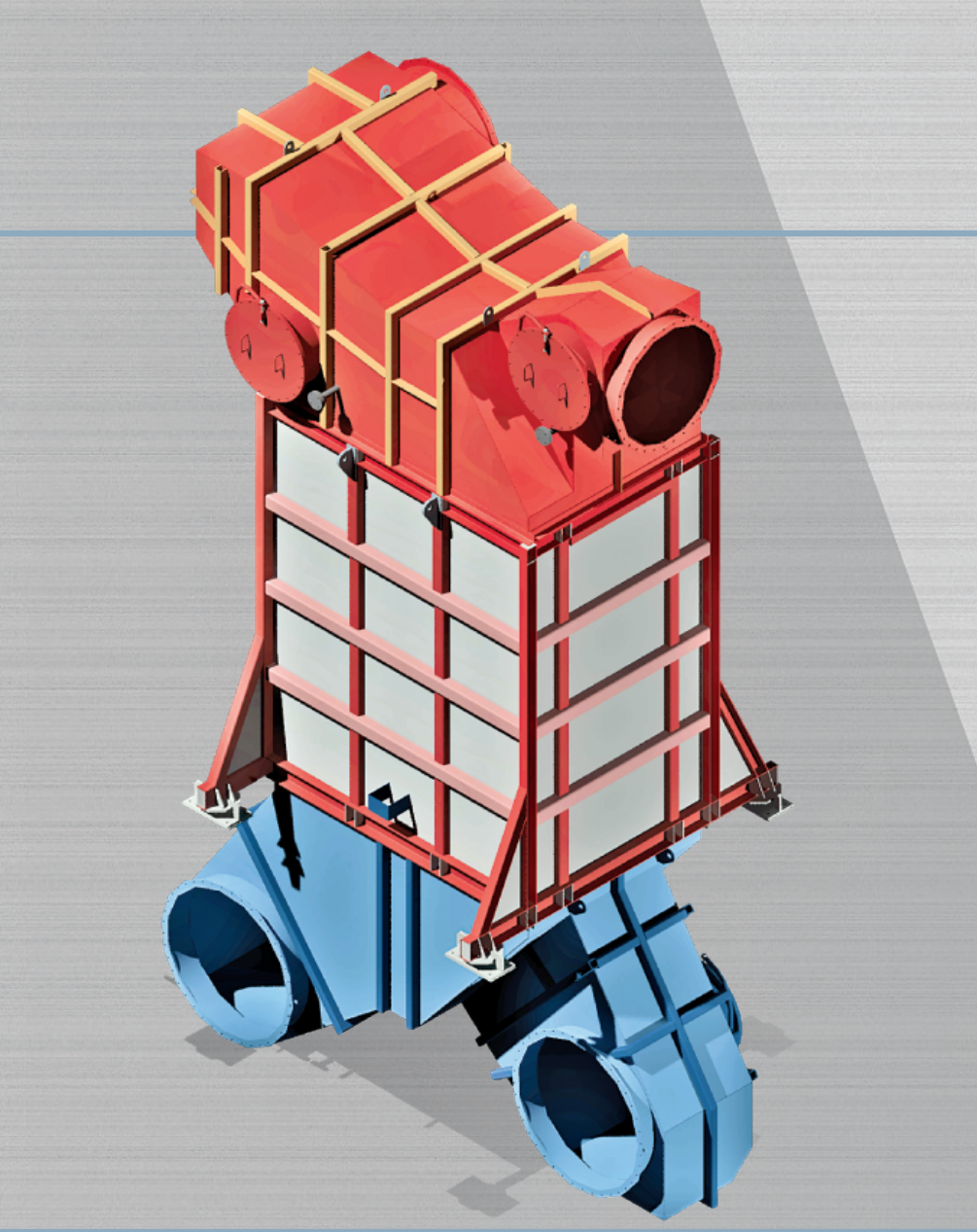

Steam heaters

Whether cold air bypasses, hot air recirculation, ferrules or corrosion resistant material, we can suggest you the best approach to protect the cold end of your equipment. Should steam be available on site, our steam heat exchangers can be combined with other equipment or serve as a stand-alone solution to raise process gas temperatures.

About plate-type heat exchangers

Plate type heat exchangers are suited to replace cast-iron type, tubular-type or rotating type heat exchangers in non- or low pressurized applications.

Our plate packs are the core component for heat recuperation between two gaseous fluids. They come with a set of unique features on the market.

Their modular design makes it possible to easily extend the duty of the heat exchanger.

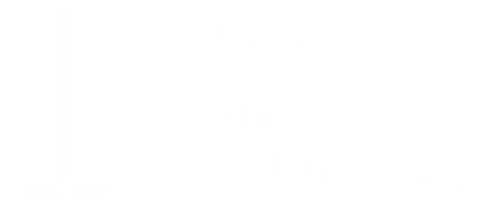

Modular installation

Plate packs are assembled to easily installable heat exchange modules, which come in different configurations of fluid flow direction. We offer a variety of configurations depending on the project requirements.

Flexible fabrication and deep understanding help us choose, mix and evolve the optimal flow pattern for plants and applications: counter-flow, cross-flow or counter-cross combinations.

Heat exchanger modules are typically arranged in either one single pass or in multi passes, depending on the heat recuperation targets.

A patented design

Heat exchange modules can be assembled to combustion air preheaters for industrial furnaces. With zero leakage and optimized lifetime to maximize energy savings and reduce carbon dioxide emissions.

A patented design with bi-metal plates to account for specific industry requirements sets us apart from our competitors.

High corrosion resistance allows unprecedented levels of heat recuperation at operating temperatures well below the acid dew point. All in just one single pass.

A team at your service

We will be happy to offer the best solution that suits your business.

Save money with our solutions

Reduce your fuel consumption and CO2 emissions